Maintenance Tips

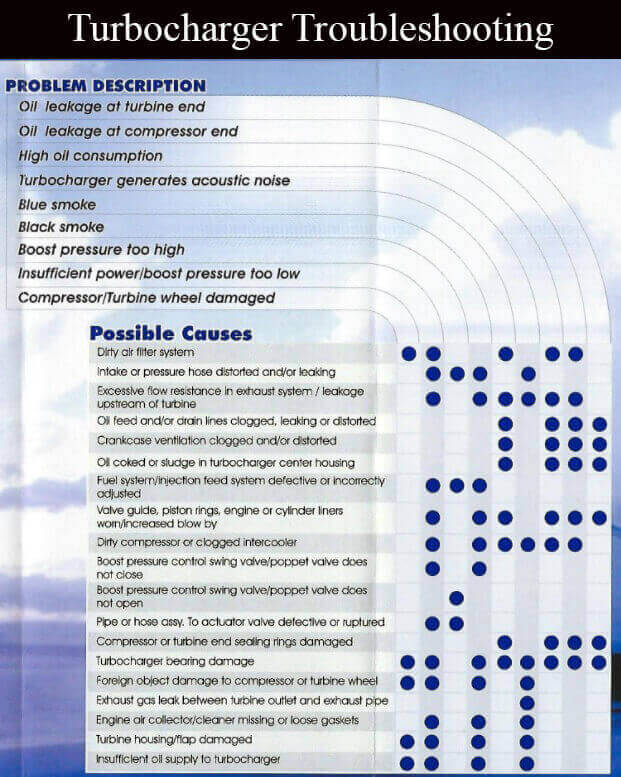

Below are a few charts and things to help you troubleshoot your turbocharger or injector issues. Test Calibration stays current on all of the latest diesel technologies. We are fully staffed with certified and trained people to get you up and running again. If you have any questions, please do not hesitate to Contact Us today!

Why Turbochargers Fail

Turbochargers "fail" for a number of reasons. Some of these reasons include:

- Foreign object damage.

- Contaminated oil supply.

- Restricted oil supply.

- Maybe issues related to the turbo oil drain system and/or the engine breather system.

More specific reasons why your turbo may fail are:

- Contaminated oil

- Dirty oil

- Lack of lubrication

- Low oil pressure

- Kinks in the oil inlet lines

- Clogs in the oil inlet line

- Plugged air cleaners

- Collapsing hose connections

- Undersized air pipes

- Prolonged engine idling

- Over-fueling

- Hot engine shut-down

- Improperly installed gaskets and nuts/washers dropped into the exhaust system.

Preventing Turbocharger Failure

Taking preventative measures when using a turbo-charging system can and will increase the life of any turbocharger. Keep in mind these steps when using a turbo-charging system:

- Keep clean oil in your engine.

- Keep the air filter clean and unrestricted.

- The duct work from the air cleaner should be free of holes.

- The duct work connections should be tight to prevent leaks.

- Warm up the engine for two to five minutes prior to throttling up and let engine idle for approximately 2 minutes prior to engine shut down.